Project

Case Studies: Double Enveloping Worm Gears and Reducers.

We present various successful implementations developed and

delivered through EasternGear’s proprietary technology.

Improved Performance and Unified System Development for AMR Lift Modules

1. Project Overview

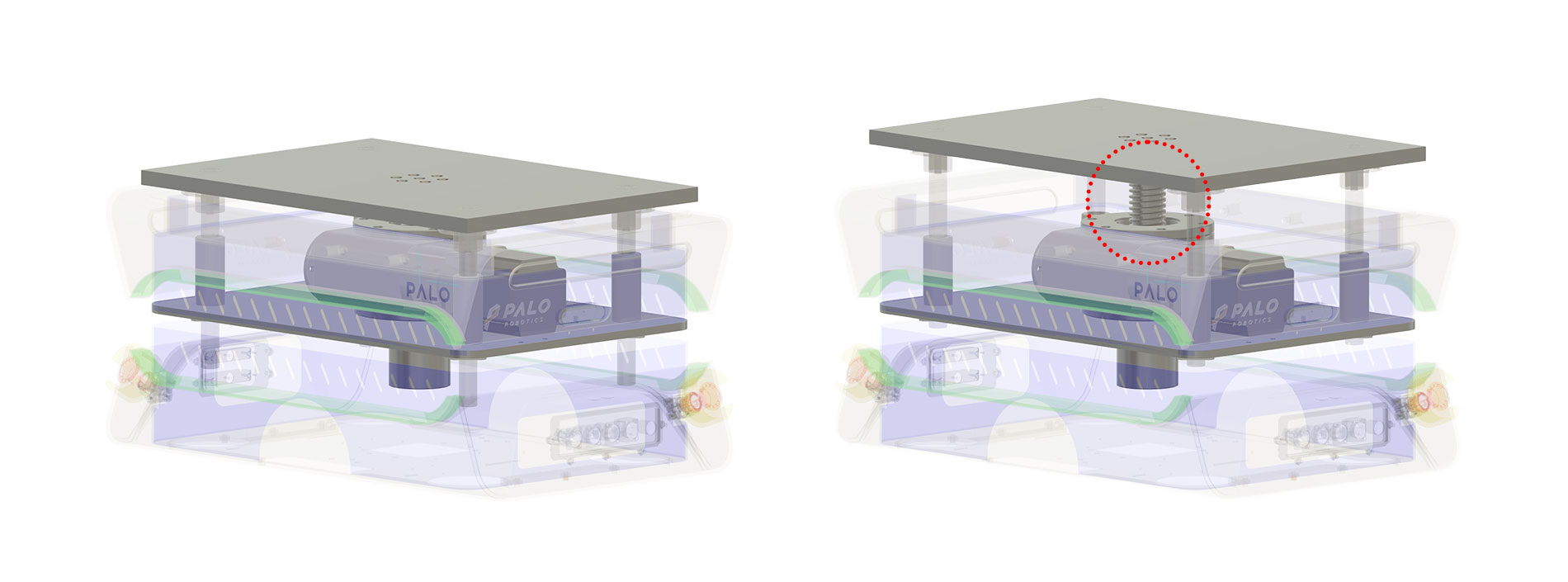

This project was initiated as part of the smart factory system integration of a domestic manufacturer “L”, aiming to enhance the performance and finalize the productization of a lift module mounted on top of an AMR (Autonomous Mobile Robot).

This lift module is a core component of the automated logistics system within the factory, enabling automatic lifting and transportation of materials between multi-level workstations. A compact reducer structure that can be installed in the limited upper space of the robot while ensuring high output and high-precision operation was a key requirement.

📌 Project Summary

✅ Reducer Type: Globoid Worm Gear, Center Distance 50mm

✅ Max Payload Capacity: 600kg

✅ Lifting Mechanism: Precision screw jack type

✅ Testing Completed: Q2 2025

✅ Planned Applications: Smart factories, automated logistics systems, collaborative robot-based work cells

2. Problem Diagnosis & Technical Analysis

The standard worm reducer structure, previously used in various industrial automation systems over many years, has revealed several technical limitations in modern smart factory environments that demand compact design and high-precision control, particularly in autonomous mobile robots (AMRs). These limitations become even more apparent in modular structures that incorporate lift functionality.

The most critical issue was the degradation of output efficiency and precision. The conventional worm gear system, based on simple line or point contact, leads to increased friction and wear under heavy loads. Over time, backlash accumulates between gears, making it difficult to maintain positional accuracy. For lift systems that require repetitive vertical motion, this positional deviation can compound and significantly reduce product quality and overall process reliability.

Moreover, traditional worm reducers are bulky and require a relatively large installation space, making them inefficient for the limited space available on top of AMRs. In cases where a multi-layered module must be mounted on a robot chassis, the overall height must be restricted, turning the reducer’s physical size into a design constraint.

▪️ Issues with Backlash and Power Transmission Efficiency

▪️ Inefficient Heat Dissipation and Output in Tight Spaces

▪️ Large Reducer Size Limits Structural Design Flexibility

These structural and functional constraints are unsuitable for the high-precision, high-reliability automation systems required in cutting-edge smart manufacturing environments. As a result, the following technical solutions became essential:

▪️ Support for Heavy Loads (600kg capacity)

▪️ Minimized Installation Footprint

▪️ Improved Reducer Output and Precision

3. Development Process

1. Technical Alternative Proposal

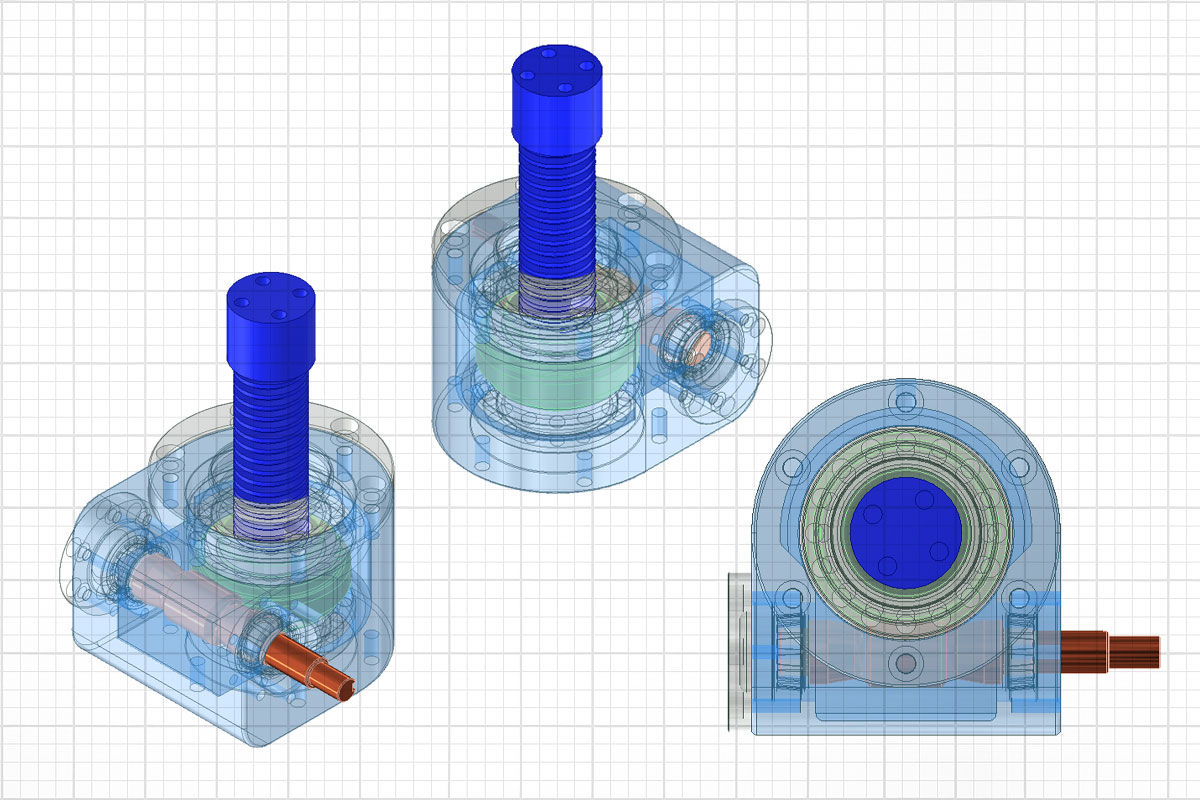

To address structural and functional limitations, we adopted a Globoid Worm Gear in place of the conventional worm gear system.

This gear mechanism utilizes surface contact rather than point or line contact, significantly improving output efficiency and precision. Even with the same center distance (CD50), the globoid worm gear provides greater load capacity and enhanced durability. Thanks to its reduced friction loss and consistent precision under repeated use, this gear structure offers higher output with a smaller installation footprint compared to general worm reducers.

In this project, we integrated the reducer, motor, and screw jack into a single unit, simplifying the overall structure and enhancing space efficiency.

The system has been optimized through EasternGear's precision machining expertise and custom design capabilities, enabling a compact configuration suitable for mounting on the upper section of the AMR platform. It was verified through extensive testing to ensure structural stability and operational reliability under repeated conditions.

→ Proposal to replace the conventional worm gear system with a Globoid Worm Gear

→ Achieves a broader contact surface and higher efficiency within the same CD50 center distance

2. Optimized System Design

▪️ Structural support shaft penetrating both the top and bottom sections of the module

▪️ Integrated motor-reducer unit for improved modular compactness

▪️ High-precision screw jack system for lifting functionality

▪️ Cable routing and anti-rotation guide designed for internal spatial constraints

3. Performance Testing & Feedback Integration

▪️ Repetitive load testing with a 600kg payload

▪️ Driving, lifting, and return testing on the AMR chassis with the module mounted

[Repetitive Up-and-Down Motion Test of the AMR Lift Module with a Fixed Load]

4. Improvement Results

✅ Space Efficiency

→ Installation footprint reduced by over 25% compared to the previous design

✅ Enhanced Output & Precision

→ Power transmission efficiency improved by approximately 30% with the application of a globoid worm gear

→ Achieved repeatable positioning accuracy within 0.1mm during transport operations

✅ Integrated Modularization

→ Unified design integrating reducer, motor, and screw jack enables easier maintenance and assembly

✅ Industrial Applicability

→ Scheduled for implementation in smart factory automated material handling systems

→ Customizable to various height and load requirements based on client specifications