Product

With a diverse lineup of reducers including servo motor reducers, slew drives, and screw jacks,

we provide high-performance gear reducer solutions optimized for various industries such as

industrial robotics, defense, heavy industry, and electric vehicle (EV) manufacturing.

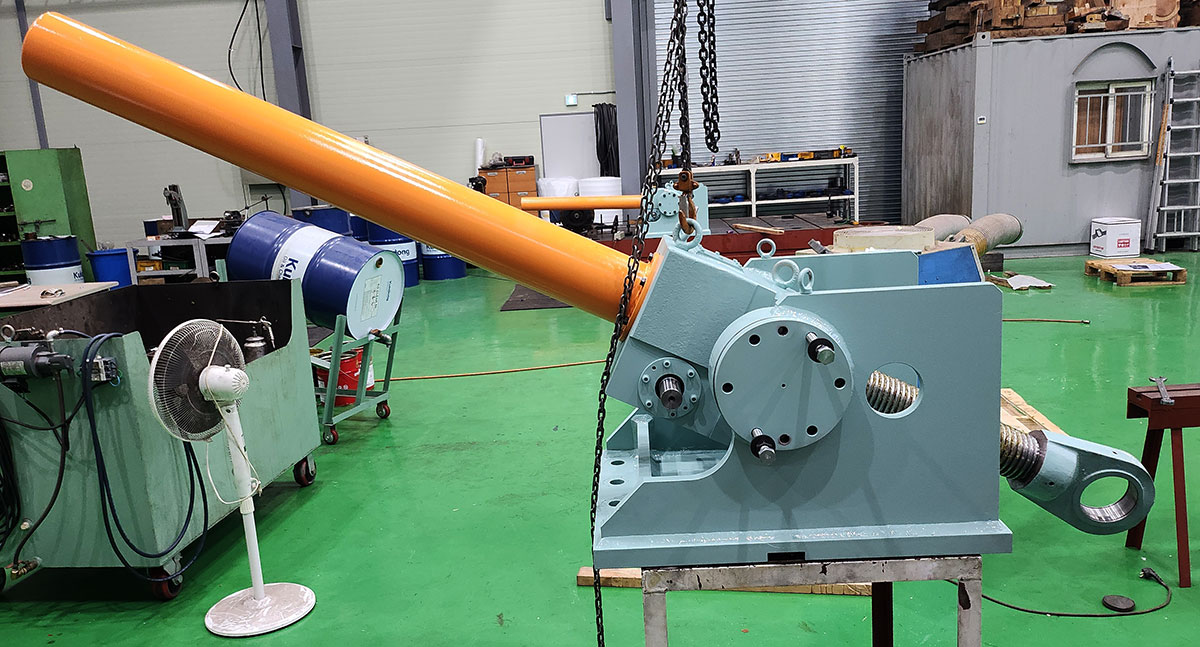

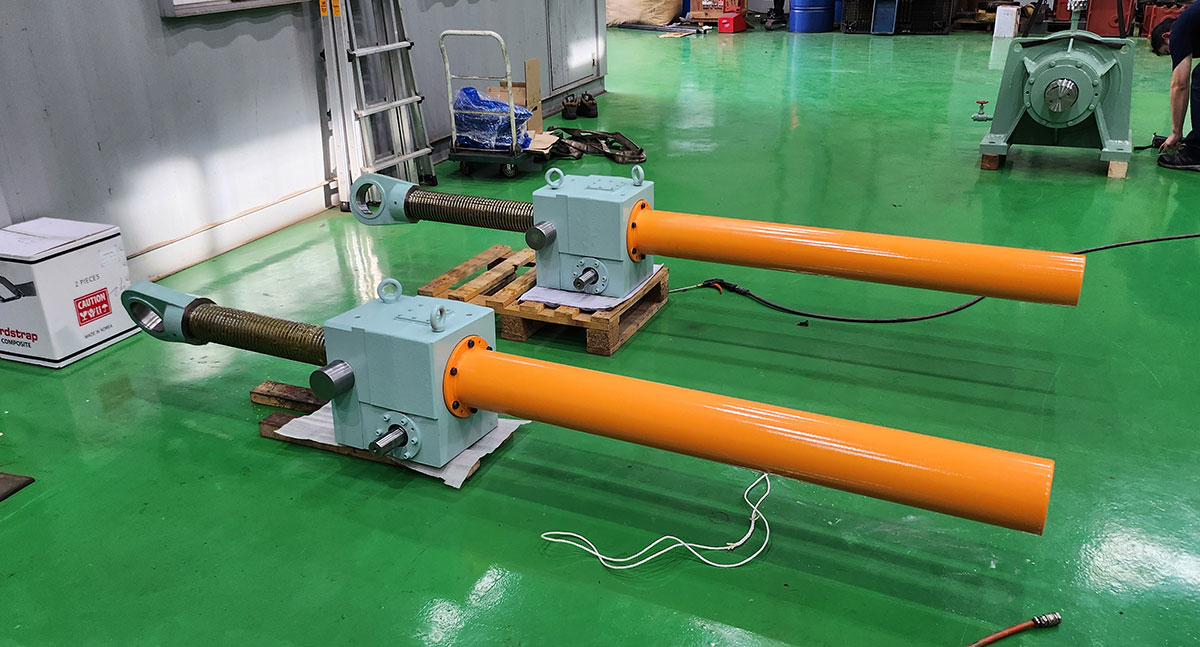

EGSC

Screw Jacks

EasternGear’s Screw Jacks are engineered for high load-bearing capacity and precision lifting control. They provide reliable performance in diverse industrial environments where accurate positioning and movement—such as height or tilt adjustment of heavy loads—are required. Through an optimized power transmission design that converts rotary motion into powerful linear motion, we guarantee a robust structure, long service life, and stable operation even under the most demanding conditions.

◆ Key Features

- High Load Support & Precision Lifting Control

The combination of a precision-machined worm gear and screw shaft enables powerful load-bearing capacity and error-free positioning control simultaneously.

- Enhanced Safety with Self-locking Function

By adopting a Globoid Worm Gear, which is even more robust than standard worm gears, the system maintains a strong holding force even if power is cut or the drive is interrupted.

- Choice of Various Screw Types (Ball Screw / Trapezoidal Screw)

Customers can choose the optimal type between a Ball Screw or a Trapezoidal (Acme) Screw depending on the application. It supports both vertical and horizontal installation, offering high design flexibility.

- Easy Maintenance & Long-Life Design

Internal wear is minimized through the use of high-strength materials. The design ensures a long lifespan with simple maintenance, even after prolonged industrial use.

◆ Applications

-

Industrial heavy load lifting systems

-

Rolling mills: roll gap adjustment devices

-

Slab and billet lifting and tilting tables

-

Electric furnace and continuous casting facility door and cover lifting devices

-

Large-scale press and mold replacement lifting systems

-

Heavy-load conveyor height and incline adjustment systems