Product

With a diverse lineup of reducers including servo motor reducers, slew drives, and screw jacks,

we provide high-performance gear reducer solutions optimized for various industries such as

industrial robotics, defense, heavy industry, and electric vehicle (EV) manufacturing.

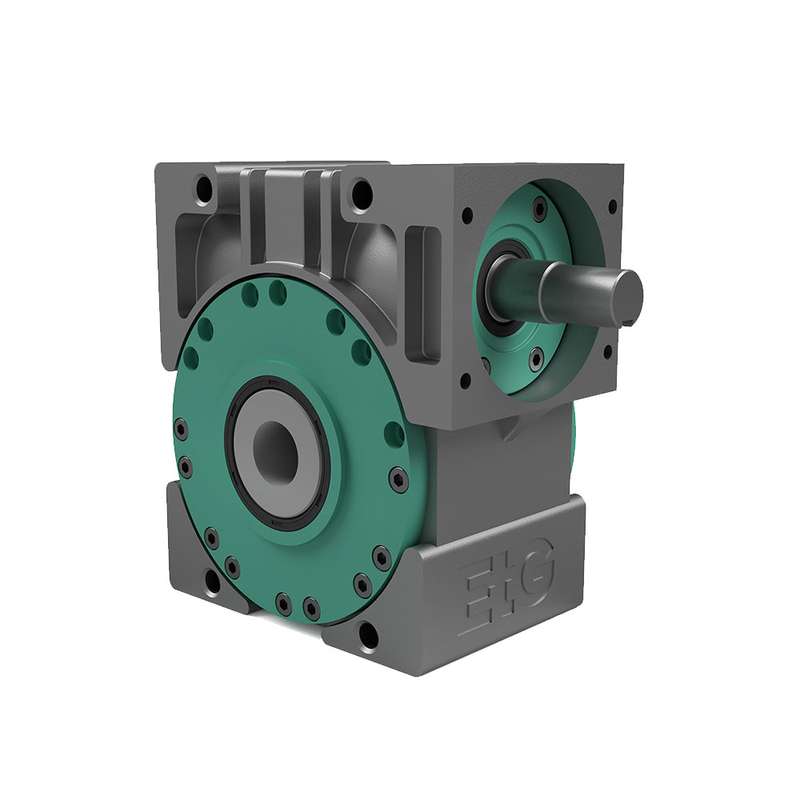

EtG-HT

High-Power Worm Reducer

EasternGear’s high-power worm reducers are engineered based on powerful torque and unrivaled durability, delivering peak performance in heavy-duty environments such as heavy machinery and large-scale industrial equipment. Through innovative Globoid design technology, we maximize power efficiency while dramatically enhancing space utilization for large drive units with a more compact structural design.

◆ Key Features

- [High Load Capacity] Superior Power via Simultaneous Surface Contact

By distributing loads across multiple teeth through simultaneous surface contact, our reducers achieve over 200% more durability compared to standard worm reducers while minimizing wear and heat generation.

- [Exceptional Torque Density] 30% More Compact

Delivers the same performance as conventional worm reducers with a size reduction of 30% or more. This allows for the construction of powerful power transmission systems in confined spaces while reducing the overall weight of the equipment.

- [Energy Optimization] High Transmission Efficiency up to 97%

Our design minimizes dynamic friction, improving efficiency by more than 10% compared to typical worm gears. This reduces operating costs for large-scale facilities by minimizing energy loss and maintains consistent efficiency even in harsh conditions like high heat and humidity.

- [Global Standard Reliability] ANSI/AGMA 6135-A02 Compliance

Based on verified data and precision machining technology, we meet the stringent quality requirements of the global market, ensuring stable operation over the long term.

◆ Applications

- Heavy Industry & Construction: High-torque drive units for excavators, large cranes, winches, etc.

- Automated Manufacturing Lines: High-load handling processes for EV body transport and large presses.

- Plant Equipment: Continuous heavy-load devices in steel mills, mining equipment, etc.

- Energy & Infrastructure: High-rigidity drive units for solar trackers, dam sluice gate controls, etc.

| Gear Tooth | Globoid or Planar |

| Center Distance(mm) | 17 ~ 300 |

| Number of transmission ratios per size | 1:3 ~ 1:60 |

| Transmission ratio (i) | 5 up to 5,250 |

| Efficiency up to (%) | 85 ~ 97 |

| Torques up to (Nm) | 364,000 |

| Self-locking | optionally |