Core

Technology

Core

Technology

Globoid Worm Gear / Double enveloping Worm Gear

Simplistic

Structure

High Force

Transmission

Size reduction

possible

Cylindrical Worm Gear:

Cylindrical Worm Gear

Globoid Worm Gears

Globoid Worm Gear

Globoid Worm Gear US Patent

(1925, S.I. Cone)

Globoid Worm Gear

International Standard

ANSI/AGMA 6135-A02

ANSI/AGMA 6135-A02

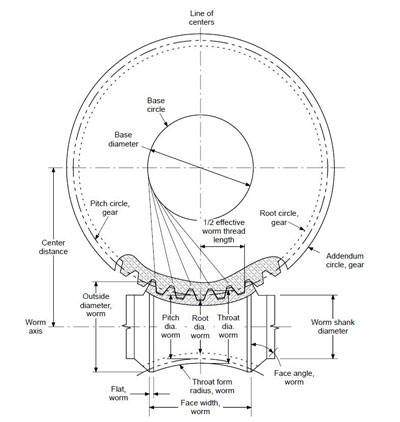

Globoid Worm Gear (Double enveloping Gear)

Globoid Worm Gear Gearset central plane

Globoid Worm Gear Gearset central plane

EasternGear

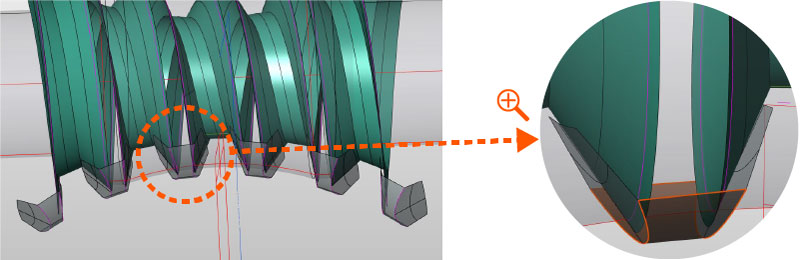

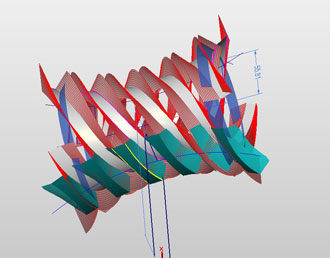

Globoid Worm Gear 3D Design

Globoid Worm Gear Contact Image

Comparison of Gear Contact Pattern Before Running-in

Comparison of Gear Contact Pattern After Running-in

Gear Contact Pattern After 8 Hours of Running-in

We have developed algorithms accounting for geometry and topology from product design, modulation, manufacturing, and performance testing.

Simulating our gear reducers and gear contact structure virtually with digital simulation programs.

Analysis and

Design

In-house Processing

of Key Parts

Gear Fit

Test

Product

Assembly

Final Performance

Test

Design

In-house Processing of Key Parts

In-house Processing of Key Parts

Gear Fit Test

Product Assembly

Final Performance Test