PROJECT GOAL

Development of a 5 DoF collaborative robot arm.

Collaborative

Project

EasternGear strives for collaboration and coexistence.

We consider these as our core values for success.

We work with experts in various fields, including companies

and research institutes to create opportunities to grow together.

PROJECT GOAL

Development of a 5 DoF collaborative robot arm.

MISSION

RESULT

50%

50%

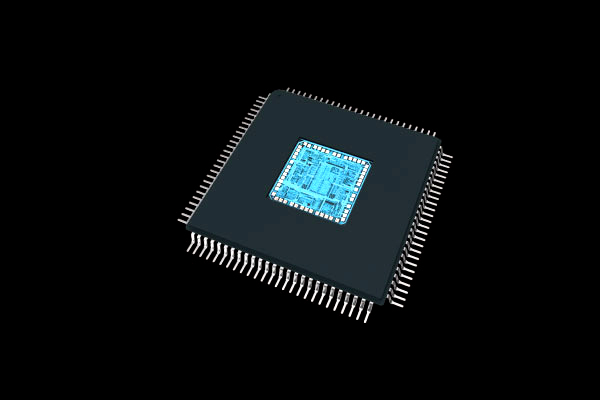

KEY TECHNOLOGY

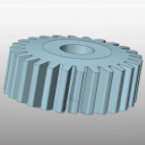

To address the monopolistic technology and sales by large companies and countries with a stronghold in the tech industrial market, we took on the challenge of developing an innovative robot joint drive using globoid worm gears at the articulation of the arm. We intend to reduce the manufacturing costs while improving payload capacities compared to existing products with similar specifications.

PROJECT GOAL

Developing a metal processing method for miniature gears used in power tools

MISSION

RESULT

60%

36sec

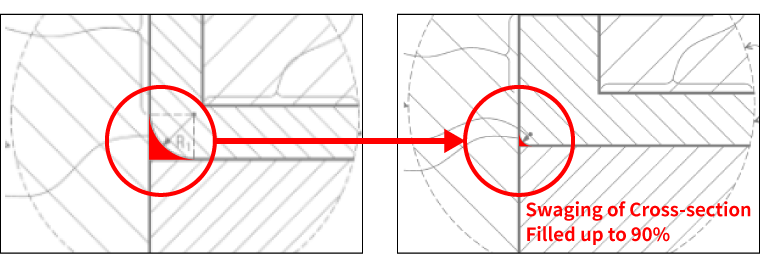

KEY TECHNOLOGY

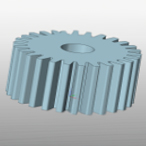

We have reduced costs and shortened production processing time by using a press processing method instead of CNC machining. By applying our own technology and years of experience, we have reduced the die roll R that can occur due to press processing by 90%. Enabling the expansion of gear contact area and reducing output loss.

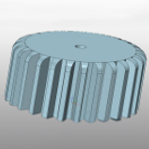

The outer surface of the product using existing processing methods

The outer surface of the product using our newly developed press die processing methods

5-Step Process | Total Time: 300 second

4-Step Process | Total Time: 36seconds